The operating department is a place for providing surgeries and emergency treatments to patients. As a crucial technical department in hospitals, the operating department has extremely high requirements for air quality, as

good air quality can effectively ensure the success rate of surgeries and reduce the risk of infection during procedures. As to what purification air conditioning system and what cold/heat source can be used for the operating department, we should conduct comprehensive analysis of the surgical conditions and annual operational scenarios, and make a choice taking into account comprehensive energy utilization.For example, as most operating departments are large and often have external corridors, with operating rooms in air-conditioned zones, especially during transitional seasons, when outdoor temperatures drop, indoor cooling loads decrease, and human moisture loads remain unchanged, the heat-moisture ratio declines. To maintain supply air temperature and humidity, the air must first be cooled and dehumidified, and then reheated at constant humidity. This requires cooling and heating simultaneously. Traditional methods typically involve air cooling and dehumidifying through cooling coils, followed by electric or steam coil heating, resulting in cooling and heating offset and energy waste.

The fresh air heat and moisture treatment in operating departments has always been a key concern for designers. The independent temperature and humidity control system is a standalone energy-efficient air conditioning system, where the fresh air system primarily handles humidity, and the circulating air conditioning system handles temperature and cleanliness. Operating rooms with different cleanliness levels require varying circulating air volumes due to their distinct cleanliness requirements. Centralized fresh air handling not only reduces energy consumption but also simplifies the control of the entire air conditioning system, meeting the flexible operational needs of various clean operating rooms.

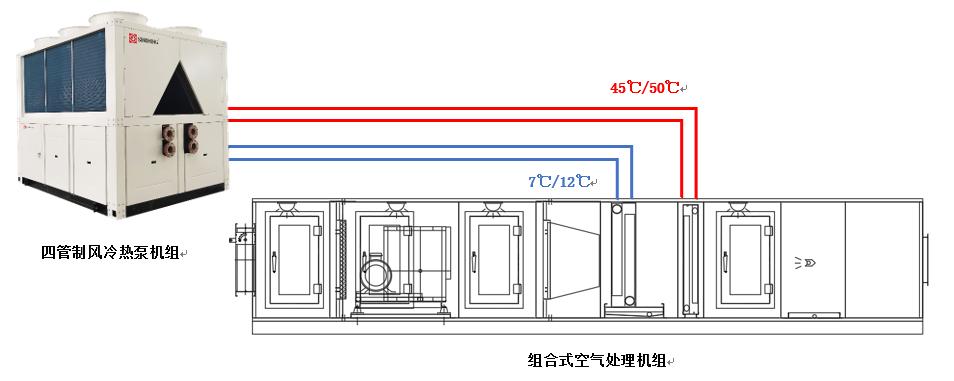

SINO KING recommends using four-pipe air-cooled heat pump units for the cold/heat source, which can operate in cooling-only, heating-only, or cooling and heating mode. While obtaining chilled water from the evaporator, the units can simultaneously obtain hot water through condensation heat from the heat exchanger, with any imbalance discharged through auxiliary heat exchangers. This meets the real-time precise control for both cooling and heating loads, and achieves cooling and heating at the same time with only one energy input. The comprehensive energy efficiency TCOP reaches up to around 8.0, significantly reducing the energy consumption.

The air handling side adopts two independent units: a centralized fresh air handling unit and a circulating air handling unit. The fresh air handling unit is equipped with functional sections such as the supply fan, filter, chilled water coil, hot water coil, and humidifier sections. The cold and heat source is provided by a four-pipe heat pump unit. The final fresh air state parameters are determined by the indoor moisture load and remain relatively stable, ensuring that the indoor moisture load is primarily removed by the fresh air—this is the humidity priority control mode of the operating room air conditioning system. The circulating air handling unit is mainly responsible for dynamically controlling the instantaneous changes in the sensible heat load in the operating room. This mode can ensure that the circulating air handling unit operates without condensate water in most cases, preventing bacterial growth in the drain pan due to water accumulation.